Qtopic - 380 Series

- Automatifc feeding paper gap control and automatic burst cutting system

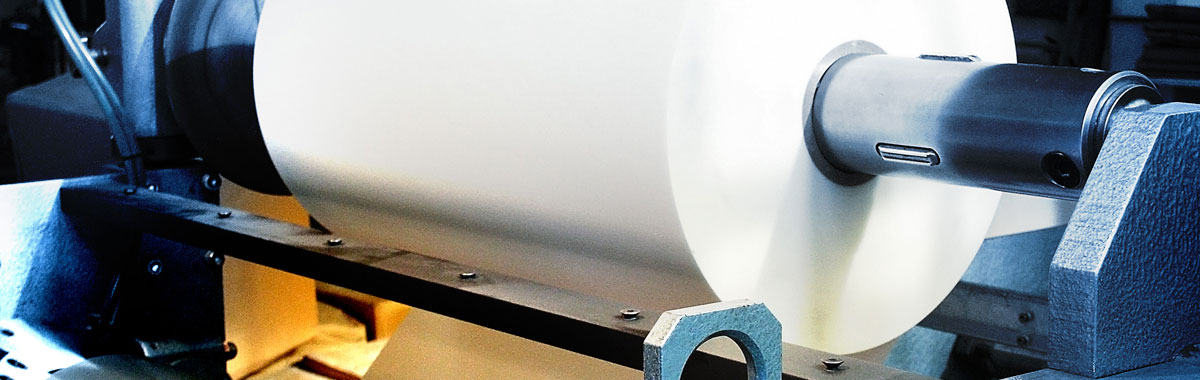

- Film tension control device is equipped

- Strengthened laminating pressure for more stepped-up bonding power effecting perfect quality of output

- Ergonomic touch screen for enhancing operator- centric convenient control & quality productivity

- Sleeking and lamination solution with re-winder unit

- Air compressor (with light weight & lower noise) is placed inside the body

- The method of forming embossing pattern by heating press mold partially on the printing surface laminated with thermal laminate film

- Using household power supply (220-240V)

| Dimension | 720*1700×1350 mm | |||

| Laminating speed | 1,5-10m / min | |||

| Paper size – MAX | 380x500mm (option 1200mm) | |||

| Paper size – MIN | 180x210mm | |||

| Substrate thickness | 120-350 g/m2 | |||

| Front roller diameter- Top | high glossy chrome 100mm | |||

| Front roller diameter- Bottom | silicon 80mm | |||

| Pressure control | Pneumatic cylinder | |||

| Laminating temp. | Max 135°C | |||

| Warm-up time | 5 min. | |||

| Heating system | Infrared Heater | |||

| Film tension control | ✓ | |||

| lamination | One-sided | |||

| Emobosing | X (option) | |||

| Sleeking / Rewinder | ✓ | |||